Mail Us: [email protected]

Call For Us: +86-15502499721

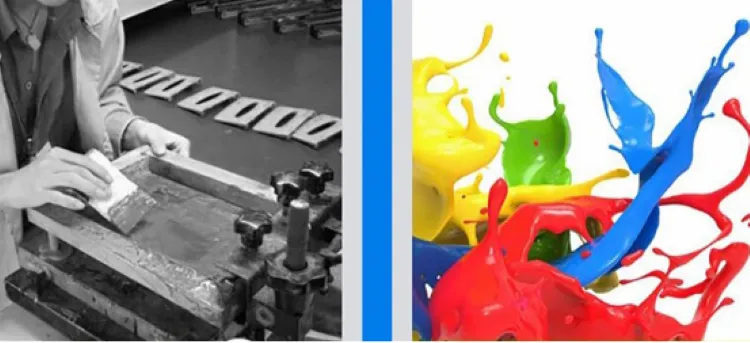

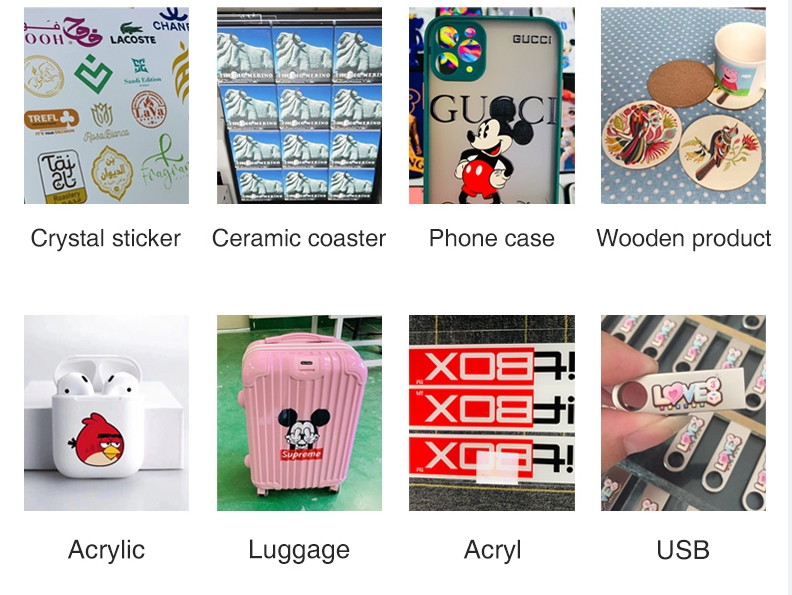

Compared with traditional printing methods, the advantages of UV flatbed printers are obvious. First of all, asa non-contact printing method, it can protect the printing material and prevent wear and scratches during theprinting process. Secondly, UV light curing technology can ensure that the printed pattern is bright in color,wear-resistant, fade-resistant, waterproof, and UV-resistant. In addition, the UV flatbed printer has high printingaccuracy and can clearly print out tiny details. It also supports multi-color and gradient color printing, providingusers with greater room for innovation. Finally, since the drying step is omitted, UV flatbed printers caneffectively improve production efficiency, becoming a work-free and extremely efficient choice in the printingindustry.

Assembly Line

High Precision

High Production Capacity

Supports Customization

Strict Quality Inspection

Quality Assurance

Two-Way Printing

High Printing Precision

Easy Operation

Ink Shortage Alarm

Even Coloring

Eco-Friendly And Durable Ink

Computer-controlled, direct printing allows for more delicate patterns and realistic, vivid colors. Richlayering and strong three-dimensional effects contribute to high-fidelity image reproduction .

Save human labor and material resources, no noise, no pollution.

A droplet size of 3.5 picoliters offers a balance between throughput and print quality, suitable for various scenarios.

Using distinct inkjet schemes tailored to various printing materials ensures precise color reproduction,distinct layering, and smooth color transitions.

When the printer is no longer in working condition, the nozzle will automatically flash to keep it moist andprevent ink from solidifying and causing clogging.

Requires multiple steps and intricate procedures

Too many material restrictions

Themachine consumes costly consumables and incurs high expenses

It consumes manpower and has lowefficiency

No need for typesetting, simple operation

Applicable to most materials, widelyversatile

Low cost, high profit margin

Human labor savings, printing speeds over 10 timesfaster

Unpleasant odor causing environmental pollution New UV ink: environmentally friendly and green

The cost of film plate making is high No need for plate making, direct printing

Complex processes with diverse varieties Just place thematerialand you can start printing

The result is rough and not suitable for fine printing UV printing offers comprehensive and vibrantcolors

It is widely used in commercial printing and personal creation in various industries such as advertising,teaching, medical, engineering and other fields. Due to its simple operation and realistic three-dimensional outputeffect, it is deeply loved by users and effectively improves the efficiency of commercial promotion and dailyproduction.

Introducing Epson printheads, known for their long lifespan, high precision, strong durability,

and low clogging rate. They offer the flexibility to select ink drop combinations based on

printing materials. Additionally, the software allows for the deactivation of flash spraying.

The nozzle design ensures reliability and smooth operation.

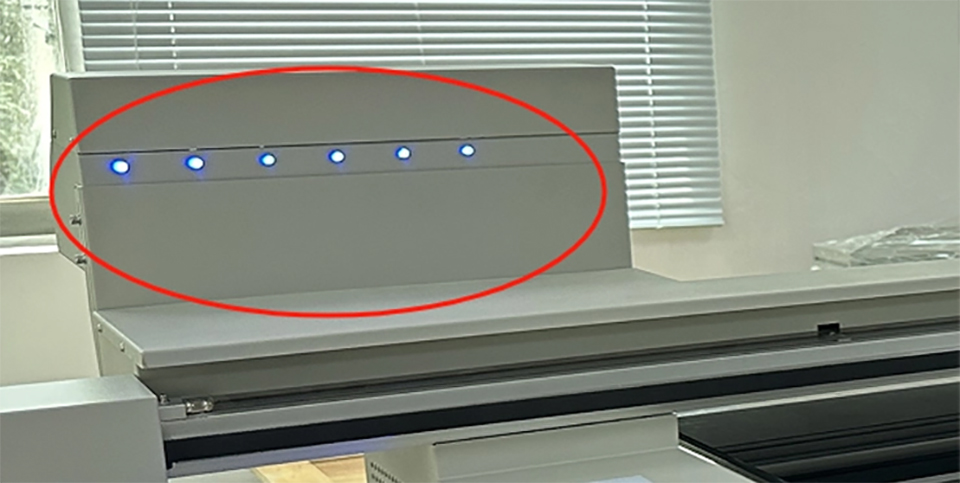

When the ink level falls below one-third, the printhead will automatically illuminate a warning

light, notifying the user of low ink levels. This feature ensures uninterrupted printing jobs,

contributing to the stability and continuity of the production process.

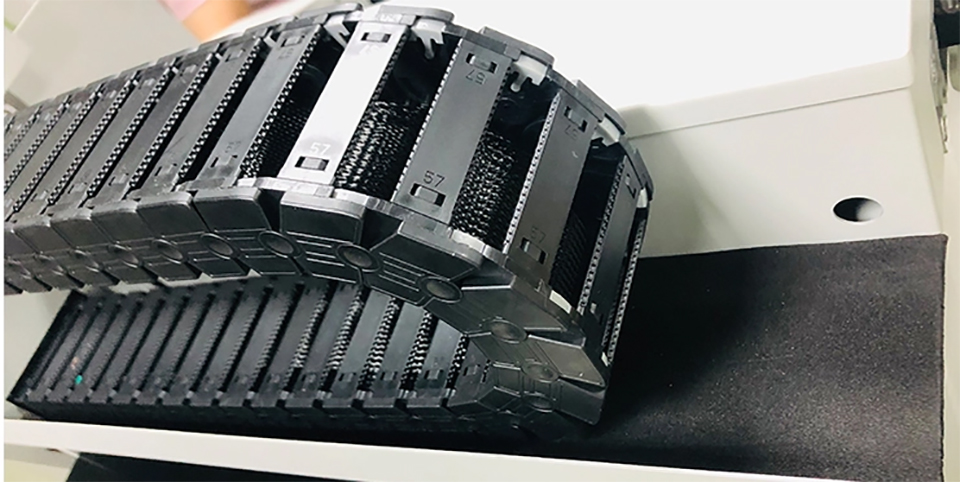

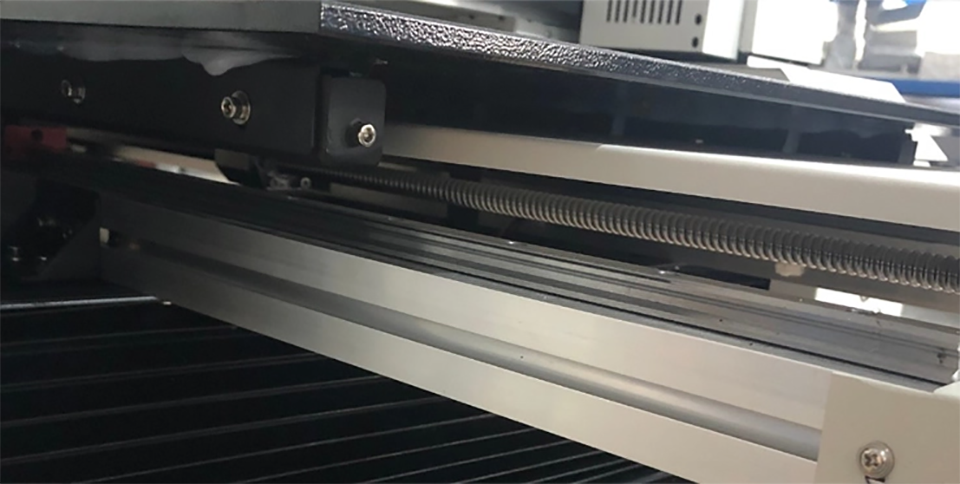

Drag chains are typically designed to reduce the noise generated during equipment operation.

Their structure and materials effectively diminish the impact of friction and vibration, reducing

the noise caused by friction between mechanical components and vibrations. This contributes

to creating a quieter working environment.

Ball screws provide higher printing accuracy and longer service life, in contrast, belts tend to reduceaccuracy and are not durable enough.

| Machine dimensions170*132*72cm | Maximum supported work size65*90cm |

| Operating SysteWindows 10/7 | Maximum working height16/18+cm |

| Packaging dimensions77*140*90cm | Net weight200KGS/260KGS |

| Print output softwareSpecialized software for managing color and white ink simultaneously alsosupporting simultaneous output of varnish (currently supporting 3heads for varnish) | Printhead and ink ConfigurationOne printhead controls color inkOne printhead controls white inkOneprinthead controls varnish |

Our friendly team would love to hear from you!

Copyright © Shenyang Faith Technology Co., Ltd. All Rights Reserved