Mail Us: [email protected]

Call For Us: +86-15502499721

Printing on plastics is the main reason why UV printing has become a revolutionary technology. UV inks are compatible with various types of plastics, including acrylic, PVC, polycarbonate, and polypropylene, and are commonly used in signage, displays, and industrial applications.

High-definition lens 1:1 output image

| Product Dimensions | ||

| 140*155*65cm | 95*102*58cm | 78*92*60cm |

| Print Size | ||

| 60*90cm | 50*60cm | 33*60cm |

| Number of Nozzles | ||

| 2 to 4 units | 2 units | 1 to 2 units |

| Net weight of the product | ||

| Approximately 108 kg | Approximately 78 kg | Approximately 73 kg |

Product Highlights

High-quality, Multifunctional ink

We use the latest ink to achieve outstanding and high-value prints,going beyond CMYK to offer you more options and flexibility.

|  |  |

| CMYK | Gloss level | White |

| Use UV/textile ink to achievestunning image quality and color gamut. | Create textures and embossing for striking graphics. | White ink opacity is improved,adding detail to image surfacesand enhancing color and contrast. |

Epson high-definition print heads (industrial grade)ensure that every detail is clear with professional software.

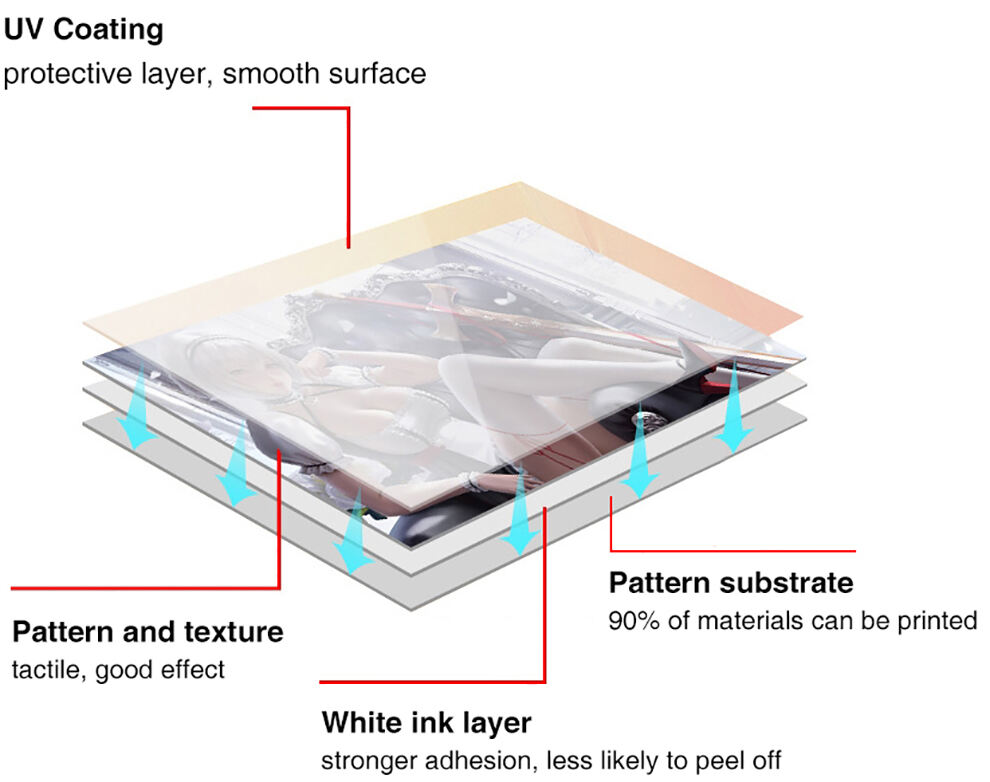

The printer features high-resolution print heads and visual recognitiontechnology, with a printing precision of up to 1200 dpi and an errormargin of only 0.01 mm. lt reproduces 99% of CMYK colors and delivers1:1 image reproduction.

High Precision

3.5PL droplet size offers a combination of throughput and print qualitymaking it suitable for a variety of applications.

High Resolution

Different inkjet schemes can be used depending on the printing materials,ensuring accurate color reproduction, distinct layering, and smooth transitions.

Smart Maintenance

When the printer is not in use, the print heads automatically perform a purge tostay moist and prevent ink from drying and causing clogs.

Automatic Cleaning

Automatic cleaning is more efficient, more stable, and requires less maintenancecompared to some non-automatic cleaning devices.

Printing Principle

Product Parameters

| Product model | A1 | A2 | A3 |

| Ink type | UV ink | UV ink / textile ink | Printhead clog prevention |

| Net weight of the product | About 108 kg | About 78 kg | About 73 kg |

| Product dimensions | 140*155*65cm | 95*102*58cm | 78*92*60cm |

| Print size | 60*90cm | 50*60cm | 33*60cm |

| Printhead configuration | Epson high-definition printhead (industrial grade) | ||

| Number of printheads | 2 to 4 | 2 units | 1 to 2 |

| Printing method | Unidirectional/bidirectional printing | ||

| Print precision | 720dpi/1440dip/2880dpi | ||

| Print speed | Adjustable three-speed: high, medium, and low | ||

| Interface method | High-speed USB transmission interface | ||

| File format | Common image formats such as Al, CDR, JPG, PNG | ||

| Printing material | For materials such as phone cases, leather, slate paintings, crystal paintings.acrylic, glass, tiles, USB drives, cards, nameplates, PP, PE, fabric,cylindrical objects, wine bottles, thermos cups, PTFE, packaging boxes, luggagetoys, etc., manual measurements may have errors; actual dimensions prevail. | ||

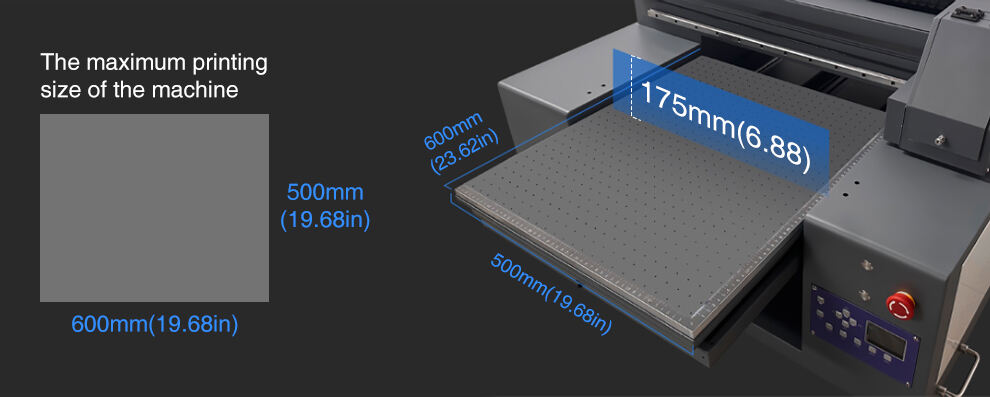

| Print height | 0-18cm | ||

| Printhead clog prevention | Automatic ink circulation + white ink agitation | ||

| Color configuration | CMYK+W+O(Cyan, Magenta, Yellow, Black + White + Varnish) | ||

| Ink supply method | Continuous ink supply system | ||

| Printhead maintenance | Automatic cleaning flash spray, and timed flash spray moisture maintenancesystem during idle periods | ||

| Curing system | LED UV lamp curing for instant drying | ||

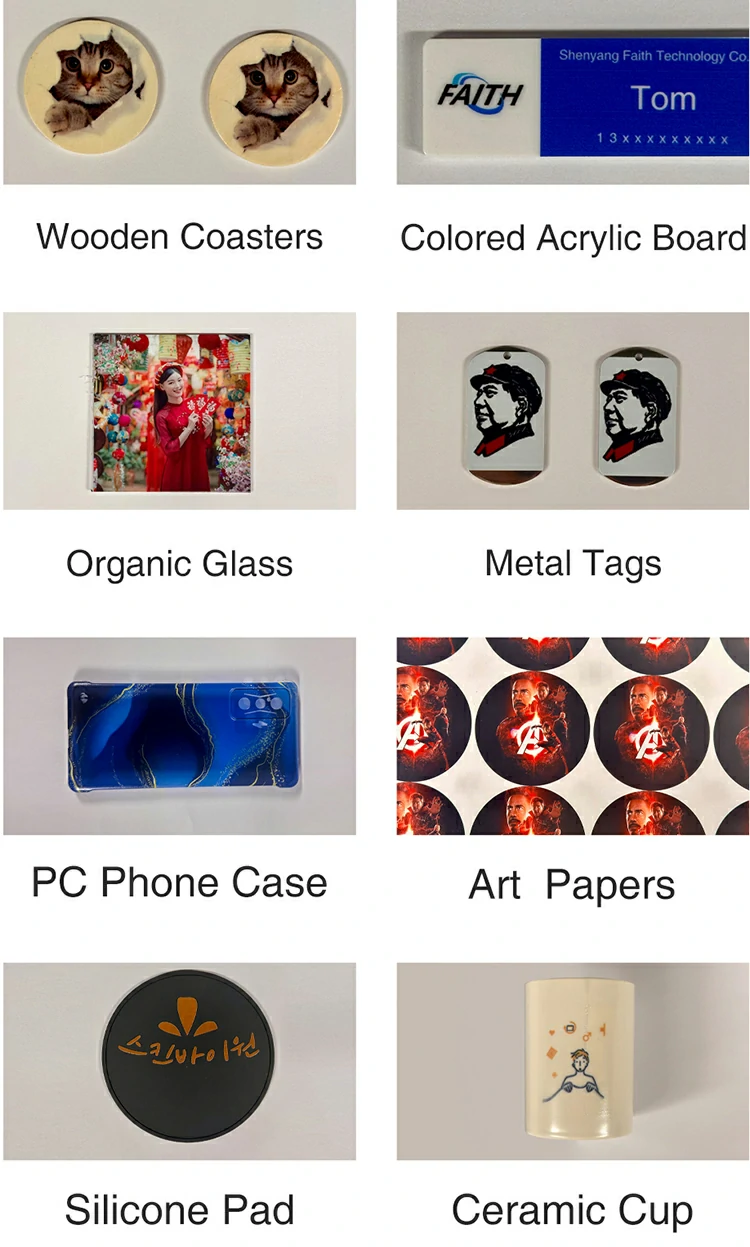

Print Sample Display

Utilizing a new ink optimization technology, this system can reduce inkconsumption by up to 30%. By lowering the levels of CMYK and increasingthe amount of black ink, the technology achieves high-precision printingresults without compromising image quality.

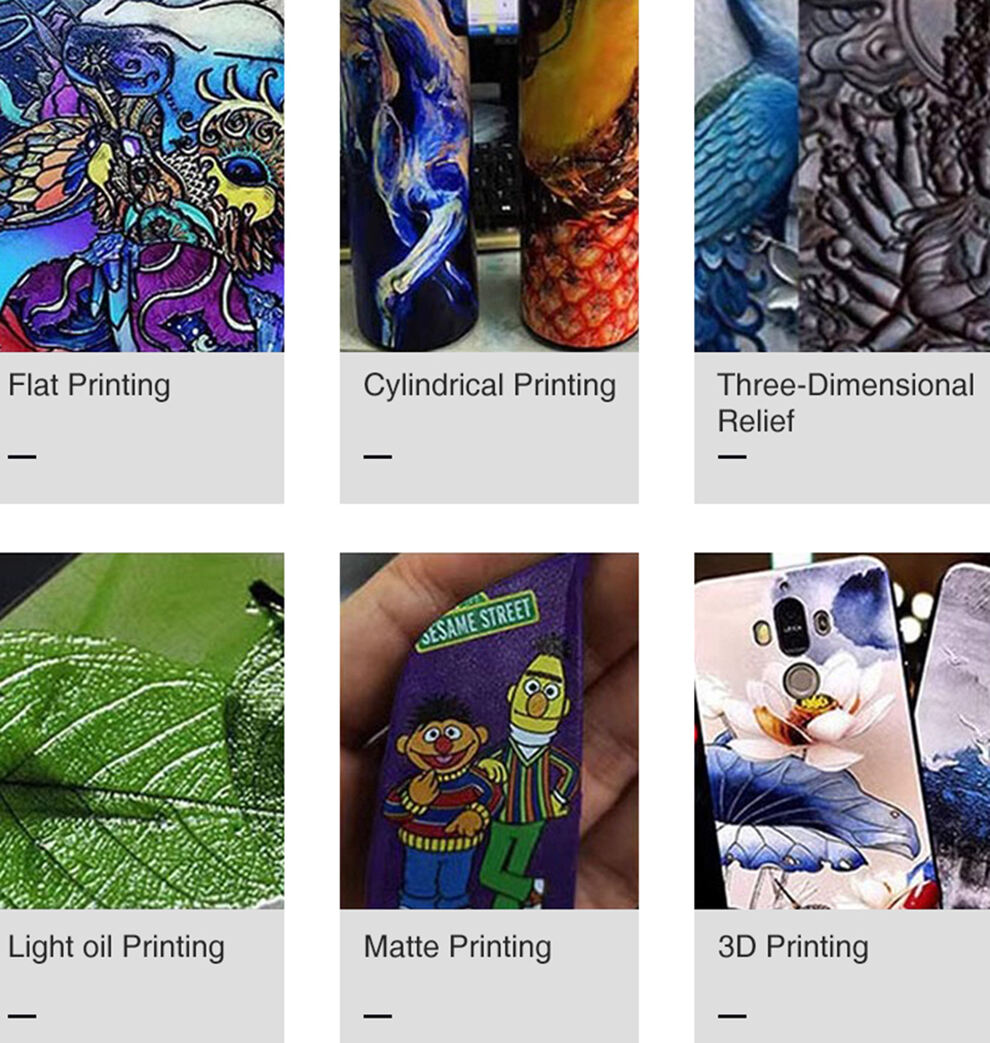

Flat / Cylindrical /Relief

Multiple printing effects can be achieved with just one machine.

Print Effect Display

Product Details

Domestic Drag Chain

Drag chains are typically designed to reduce the noise generated during equipmentoperation. Their structure and materials effectively minimize friction and vibration,helping to reduce the noise from friction and vibrations between mechanicalcomponents, thereby providing a quieter working environment.

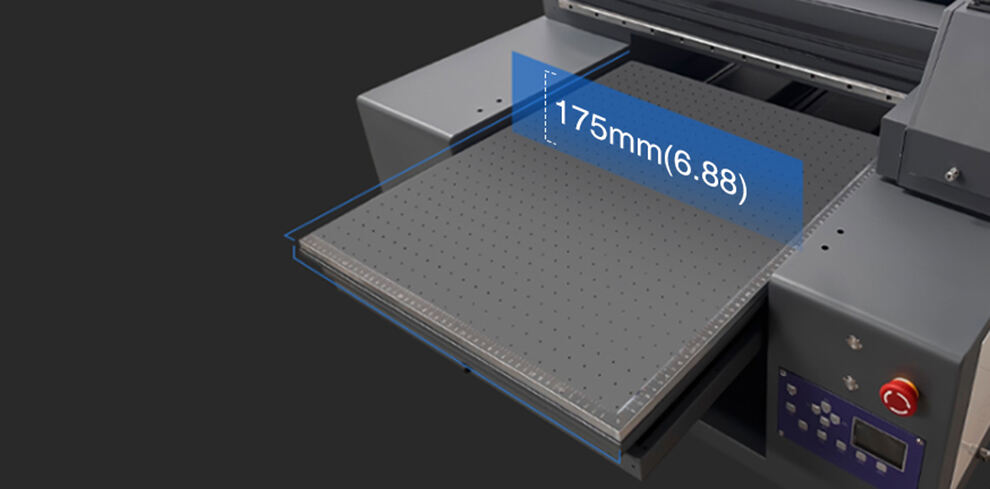

Positioning air suction

The air suction holes on the print platform are excellent for positioning.On the computer, create a frame based on the item's dimensions. Start the deviceand print the frame. Place the item on the positioning points to ensure stableadhesion, which makes the printed object more accurate.

Highly adjustable

The print media thickness can reach up to 175 mm, with a platform that can moveup and down to accommodate various printing thicknesses(can be customized higher)

Our friendly team would love to hear from you!

Copyright © Shenyang Faith Technology Co., Ltd. All Rights Reserved